Maintenance & Servicing

Committing to the purchase of equipment is one thing, keeping them operation in the long term is another. Prevention is better than a cure and in our experience equipment that is serviced regularly is less likely to fail and will cost you less in the long term.

You would always tell patients to have regular check ups so make sure your equipment gets the same level of care. We recognise that every practice is different and needs different levels of support, so we have developed different support and maintenance packages to suit your needs.

Dental Chair Servicing

If your Dental Chair fails, can you work without it?

Your Dental Chair is one of the valuable medical devices you own, and maintaining it correctly is a vital investment. Our engineers are certified and trained by the manufacturers to ensure that your Dental Equipment is maintained to the highest standards. All parts replaced are original manufacturers parts, backed up by their guarantees. Generic parts are not recommended.

What is involved?

- Remove any covers as necessary

- Follow manufacturer’s guidelines for servicing requirements, replace parts as required by manufacturer

- Switch air, water and electricity to the centre on

- Check for air and water leaks

- Test air and water outlet pressures in line with manufacturer’s guidelines

- Check tubing outlets for damage

- Check stability of the treatment centre and operation of safety limit switches

- Inspect upholstery and ancillaries, recording any damage/wear and tear

- Check operation of ancillaries, operating lights, spittoon, suction and drainage

- Ensure that the unit is returned to original settings as found

- Complete all paperwork

- Highlight any damage/wear and tear or further action required to principle/practice manager

Suction Pump Servicing

Service of the suction pump in line with the manufacturers’ guidelines will enhance the quality of suction and prolong the life of the unit. Service includes repair and preventative maintenance and the replacement of components that are worn or defective.

What is involved?

- Check and remove any collected amalgam waste and dispose of in line with practice policy

- Follow manufacturers guidelines for servicing requirements, replace parts as required by manufacturer

- Check, clean or replace where necessary any filters

- Test unit for correct operation in line with manufacturers guidelines

- Check for signs of any leaks

- Dispose of any used and contaminated parts in line with the practice policy

- Complete all paperwork

X-RAY Inspection

It is recommended that all X-Ray systems are checked annually in line with MHRA April 2015 Managing Medical Devices. The Guidance Notes for Dental Practitioners on the Safe Use of X-Ray Equipment also states that “routine tests should normally be carried out”

What is involved?

- Review the paperwork from the previous visits

- Check the stability of the X-Ray mount and arms

- Check for any damage to the tube head

- Check the electrical and mechanical safety

- Check the condition of the X-Ray exposure control

- In the case of a panoramic X-Ray set, check the rotational movement of the X-Ray tube head and the fitting

- Complete exposures tests & record the results (patient entrance dose [mGy], kV, exposure time, filtration)

- Ensure that the exposure settings are as found on arrival

- Results will be sent to the department RPA for review

- Complete ‘X-Ray Service’ report paperwork, report will then be issued to the practice

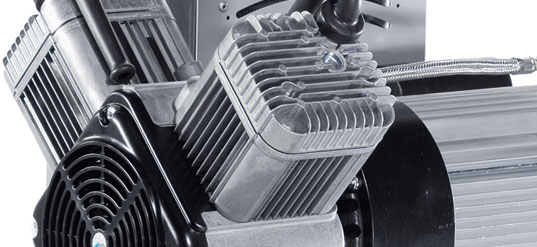

Compressor Servicing

Servicing is available on the majority of leading dental compressors.

- Employers must ensure that all work equipment is available, safe, fit for purpose and in good working condition

- All dental equipment must be serviced and maintained in accordance with the manufacturers’ recommendations

- Records of servicing, inspection and user validation checks must be kept and audited

- All members of staff must be fully trained in the safe operation compressors prior to use

What is involved?

- Switch off & drain air

- Thoroughly clean the exterior

- Inspect all welds, check all joints and seals for leaks

- Remove the safety relief valve

- Test the pressure of the safety relief valve and replace

- Check inside the tank for any signs of corrosion or cracking

- Switch on, check again for any air leaks

- Check all correct pressures are reached

- Replace oil and filters

- Complete all paperwork

Practice & Product Service Contracts

Annual Service and Preventative Maintenance

Preferential hourly rate for any calls outs

Validation and pressure vessel inspections (if required)

Certification and advice on compliance with CQC standards

Includes all standard service parts

5% discount on all non-standard parts

Annual Service and Preventative Maintenance

Includes limited call out on breakdowns

Preferential hourly rate for any extra calls outs

Validation and pressure vessel inspections (if required)

Certification and advice on compliance with CQC standards

Includes all standard service parts

10% discount on all non-standard parts

Annual Service and Preventative Maintenance

Includes unlimited call out on breakdowns

Equipment maintenance training

Validation and pressure vessel inspections (if required)

Certification and advice on compliance with CQC standards

Includes all standard service parts

15% discount on all non-standard parts

Get in Touch

Would you like more information on Ai Healthcare? Fill out the form below or give us a call on